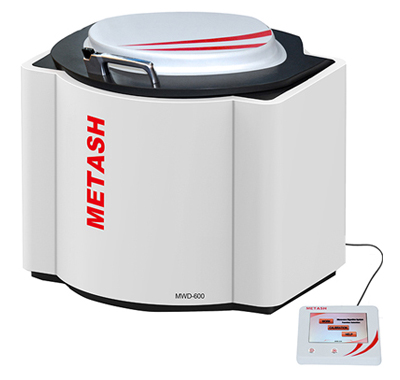

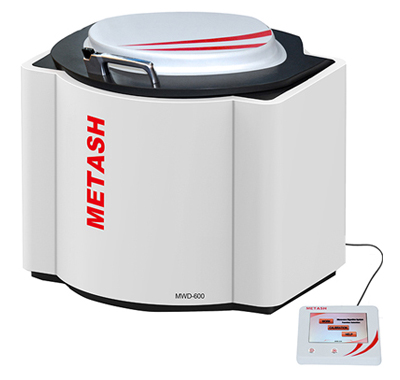

MWD-600

Microwave Digestion System

MWD-600 is a new developed microwave digestion system with all vessels temperature and pressure control. With IR temperature measurement method, our digestion system can realize real-time temperature monitoring of each individual sample. With special mechanic design, the consumable free microwave digestion system is of safety and friendly operation and durability.

Features and Functions

- 60L industrial grade chamber is made of 316 stainless steel with PFA coating to prevent emissions and corrosions.

- Contact free pressure control and IR temperature control techniques to measure pressure and temperature of each individual sample.

- Intelligent protection system will alarm and self protect when temperature and pressure turn to abnormal conditions which ensures operation safety.

- Contact free temperature and pressure measurement which avoids cross-contamination.

- Outer vessel made of PEEK glass which prevents corrosion and high temperature is high quality material which assures operation safety

- The system is design to avoid of leakage after over-pressure release which saves batch samples and solutions so as to reduce cost.

- The system releases pressure vertically to ensure safety during operation.

- The continuous 360° rotation design assures even digestion and makes system shelf life longer.

- Lid locking design with multiple protection greatly improves user’s ease of handling.

- 12 vessels/batch digestion capacity improves sample preparation efficiency. Individual frame for each vessel makes operation convenient and meets different application requirements.

- Multi safety protection functions double door prevention, temperature monitoring, high temperature prevention, pressure monitoring, high pressure prevention, instruments abnormal sound monitoring, and lid locking prevention.

- No consumables are necessary for the microwave digestion system for use which makes uses more convenient

Technical Specification

| Model | MWD-600 |

|---|---|

| Sample Quantity | 12 ea |

| Chamber | Round Oven Chamber Deaign |

| Sample | 100ml |

| Pressure Control | Full Scanning |

| Pressure Measurement | Touch-free |

| Temperature Control | Full Scanning |

| Temperature Measurement | IR |

| Vessel Material | Inner Vessel:Imported TFM |

| Outer Vessel:Imported PEEK+ glass fiber | |

| Material of Explosion-Proof Frame | Polypropylene Glass Fiber |

| Maximum Working Pressure | 10 MPa |

| Maximum Working Temperature | 250℃ |

| Temperature Limit | 300℃ |

| Chamber Volume | 60 L |

| Display | 8 Inches touch screen |

| Pressure Control Range | 0-6 MPa (0-60kg/cm2) |

| Pressure Control Accuracy | ±0.01MPa(0.1kg/cm2) |

| Microwave Power | 2000W(0~2000 adjustable) |

| Microwave Frequency | 2450MHz |

| Rotation Mode | 360° continuous rotation |

| Microwave Leakage | <5mW/ cm2 |

| Power | AC 220V,10A,50/60Hz |

| Size | 640mm×630mm×590mm |

| Weight | 75kg |

Functions

- Create curve according to pressure and time and display on the touch screen.

- Measure and real-time monitoring pressure without contact.

- Set corresponding temperature and time in accordance with different conditions.

- Set corresponding pressure protection in accordance with different experiment conditions.

- 8 pre-programming digestion method and can store 255 programs, users can set parameters according or user’ requirements.

- Application for high pressure closed microwave digestion, multi-vessel microwave digestion, closed microwave extraction, closed microwave synthesis.

- Realize continuous 720° rotation which assures even digestion

- The high frequency resonance type allows for adjustments between 0-2000W

- Automatic calibration for different parameters and basic troubleshooting function.