Clean:

Because liquid is used for the sealing material, no solids come into contact between the Shaft and the Pole Piece, preventing particle generation due to friction.

PRODUCTS

Vacuum feedthrough Seal

Vacuum feedthrough Seal

A Rotary Feedthrough is a kind of sealing device: a specialized part that prevents leakage of liquids or gases.

The Rotary Feedthrough is a seal unit for rotating parts that uses the remarkable property of magnetic fluid which is held by magnetic field of magnets.

If you're interested in the components of magnetic fluid and their properties, we invite you to read the article What is a magnetic fluid? Seals come in a wide variety of types, with a wide range of properties.

You can read a general explanation of the types of seals here.

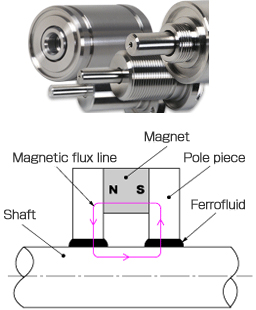

A magnetic fluid is held in the gap between the Shaft and the Pole Piece in a Rotary Feedthrough. The magnetic fluid flows along the Magnetic flux lines generated by the magnet.

The magnetic fluid maintained in the gap by the magnetic force functions like an O ring, keeping fluid from escaping even in the presence of a pressure differential.

The strength with which the magnetic fluid is held is determined by the magnet. The stronger the magnetic force is, the greater the magnetic fluid's resistance to pressure in the ring will be.

By constructing a multistage ring of Pole Pieces, it is possible to build a Rotary Feedthrough strong enough to withstand even quite large pressure differentials.

The Rotary Feedthrough uses liquid to create a seal; there is no solid-solid contact in this design.

This characteristic creates the following properties:

Because liquid is used for the sealing material, no solids come into contact between the Shaft and the Pole Piece, preventing particle generation due to friction.

By using the magnetic fluid of low vapor pressure, it can be used even in ultra high vacuum region of less than 10-6Pa.

With no solid parts in contact between the Shaft and Pole Piece, virtually no loss from wear occurs, resulting in a low-maintenance seal with a long service life.

Rigaku developed this extraordinary Rotary Feedthrough and its magnetic circuit exclusively, ensuring that the Rotary Feedthrough and the Magnetic Seal it creates deliver excellent performance.

For the secret of the Rigaku Magnetic Seal Unit, and the clean vacuum it generates, please read about Magnetic Circuit Configuration unique to Rigaku.

magnetic fluid is a fluid that is attracted to a magnet, just like iron. In the 1960s, NASA developed magnetic fluid as part of the space program. magnetic fluid has three main constituents: ferromagnetic particles such as magnetite and composite ferrite, a surfactant, and a base liquid such as water or oil. The surfactant coats the ferromagnetic particles, each of which has a diameter of about 10 nm (ten millionths of a millimeter). This prevents coagulation and keeps the particles evenly dispersed throughout the base liquid. Its dispersibility remains stable in strong magnetic fields.

This photo shows a phenomenon that occurs when magnetic fluid is placed in a container and a magnet is placed under the container. The magnetic force acting on the surface of the magnetic fluid produces 'spikes', which look like large nails sticking out of the surface. Therefore, this phenomenon is called 'spiking'.

Representations of magnetic force (shapes formed by magnetic fluid) Works presented by a graphic designer, Ms. Minako Takeno Partner companies Sigma Hi-Chemical Inc. Denshijiki Industry Co., Ltd.

Magnetic Circuit Configuration unique to Rigaku

Rigaku Magnetic Seals form powerful magnetic fields repelled each other by arranging the same pole of the magnets on both sides of a pole piece(NS-SN-NS).

The tip of the pole piece inserted in this strong magnetic field is split in two, creating a independent magnetic circuit.

The repulsion effect between the two adjacent magnetic fields focuses the magnetic flux on the tips of the pole piece to hold the magnetic fluid firmly in place.

This arrangement enables each stage of the seal to withstand even large pressure differentials.

As a result, the Magnetic Seal can be made compactly.

With this magnetic-circuit structure's ability to withstand even large pressure gradients, the gap between the pole piece and shaft can be quite large.

For the same reason, the magnetic seal can design the product of a high speed rotation or a large diameter shaft. Additionally, the magnetic circuit is housed entirely within the pole piece. This structure offers the advantages of minimizing magnetic flux leakage from the magnetic seal and protecting the magnetic field from influence from external magnetic fields.

As a result, Rigaku Magnetic Seals are relied on applications both in equipment that must be shielded from external magnetic fields (such as those from electron-beam lithography system) and in equipment on which strong magnetic fields are applied (such as large diameter silicon growth system).

If there is an opinion / demend about Products items, please feel free contact us from here.